Article Outline

Figures and tables

Volume 4 Issue 1 pp. 15-25 • doi: 10.15627/jd.2017.2

Solar Energy Gain and Space-Heating Energy Supply Analyses for Solid-Wall Dwelling Retrofitted with the Experimentally Achievable U-value of Novel Triple Vacuum Glazing

Author affiliations

a London South Bank University, Division of Electrical and Electronic Engineering, School of Engineering, 103 Borough Road, London, SE1 0AA, UK

b Centre for Renewable Energy Systems Technology (CREST), School of Mechanical, Electrical & Manufacturing Engineering, Loughborough University, Loughborough, Leicestershire, LE11 3TU, UK

* Corresponding author. Tel: +44 (0) 20 7815 7510

s.memon@lsbu.ac.uk (S. Memon)

p.c.eames@lboro.ac.uk (P. C Eames)

History: Received 25 August 2016 | Revised 9 January 2017 | Accepted 15 January 2017 | Published online 7 February 2017

Copyright: © 2017 The Author(s). Published by solarlits.com. This is an open access article under the CC BY license (http://creativecommons.org/licenses/by/4.0/).

Citation: Saim Memon and Philip C Eames, Solar Energy Gain and Space-Heating Energy Supply Analyses for Solid-Wall Dwelling Retrofitted with the Experimentally Achievable U-value of Novel Triple Vacuum Glazing, Journal of Daylighting 4 (2017) 15-25. http://dx.doi.org/10.15627/jd.2017.2

Figures and tables

Abstract

A considerable effort is devoted to devising retrofit solutions for reducing space-heating energy in the domestic sector. Existing UK solid-wall dwellings, which have both heritage values and historic fabric, are being improved but they tend to have meagre thermal performance, partly, due to the heat-loss through glazings. This paper takes comparative analyses approach to envisage space-heating supply required in order to maintain thermal comfort temperatures and attainable solar energy gains to households with the retrofit of an experimentally achievable thermal performance of the fabricated sample of triple vacuum glazing to a UK solid-wall dwelling. 3D dynamic thermal models (timely regimes of heating, occupancy, ventilation and internal heat gains) of an externally-insulated solid-wall detached dwelling with a range of existing glazing types along with triple vacuum glazings are modelled. A dramatic decrease of space-heating load and moderate increase of solar gains are resulted with the dwelling of newly achievable triple vacuum glazings (having centre-of-pane U-value of 0.33 Wm-2K-1) compared to conventional glazing types. The space-heating annual cost of single glazed dwellings was minimised to 15.31% (≈USD 90.7) with the retrofit of triple-vacuum glazings. An influence of total heat-loss through the fabric of solid-wall dwelling was analysed with steady-state calculations which indicates a fall of 10.23% with triple vacuum glazings compared to single glazings.

Keywords

Vacuum glazing, Solar energy, Thermal modelling, Energy savings

1. Introduction

The necessity to reduce CO2 emissions, in order to avoid preventable climate-change, is now largely accepted [1-4]. The UK has a commitment to reduce CO2 emissions from 1990 levels to 80% by 2050 [5]. Consequently, an ambition has been set to achieve a 50% reduction in CO2 emissions by 2025 [5-6]. To achieve this, myriad of methods and areas have been emphasised [7,8]. Here a particular focus is on dwellings by reason of its significant energy use than any other sector i.e. more than a quarter of energy use and CO2 emissions in the UK [9]. In which the natural gas consumption is dominant in providing space heating, water heating and cooking loads [10]. The majority of total natural gas consumed in around 27 million dwellings in the UK is due to space heating loads which accounted for 66% of its total usage in 2012 [4]. Over eight million of UK dwellings are having solid walls. Two important contributing factors of space-heating energy use are dwelling insulation and efficiency of heating systems. The studies have shown these solid-wall dwellings are taking retrofit measures by adopting solid-wall and loft insulation, upgrading the efficiency of boilers, ensuring proper airtightness whilst providing sufficient ventilation, and replacing existing single glazed windows to double glazed air-filled and/or double glazed argon gas filled windows and/or triple glazed air-filled windows [8,11-15]. Even though solid wall dwellings are being improved with auxiliary insulation but yet they tend to have meagre thermal performance than cavity wall insulated dwellings that has led to not meeting the building regulations. Although above mentioned measures are contributing adequately in reducing space-heating energy use but there is a need of intervention to the use of advanced technologies [5]. The focus in this paper is to comparatively analyse the use of ultra-low heat loss triple vacuum glazed windows to the solid-wall dwelling. Conventional windows can achieve the centre-of-pane thermal transmittance value (U-value) to approximately 1.89 Wm-2K-1. To achieve more reductions in the heat-loss through windows for the purpose of contributing to meeting our energy targets, vacuum glazing has a significant potential to reduce U-value down to 0.8 Wm-2K-1 [16,17]. To reduce the heat loss to a level where the U-value is less than 0.5 Wm-2K-1, the concept of triple vacuum glazing was introduced [18] and the best predicted U-value of 0.26 Wm-2K-1 was reported [19].

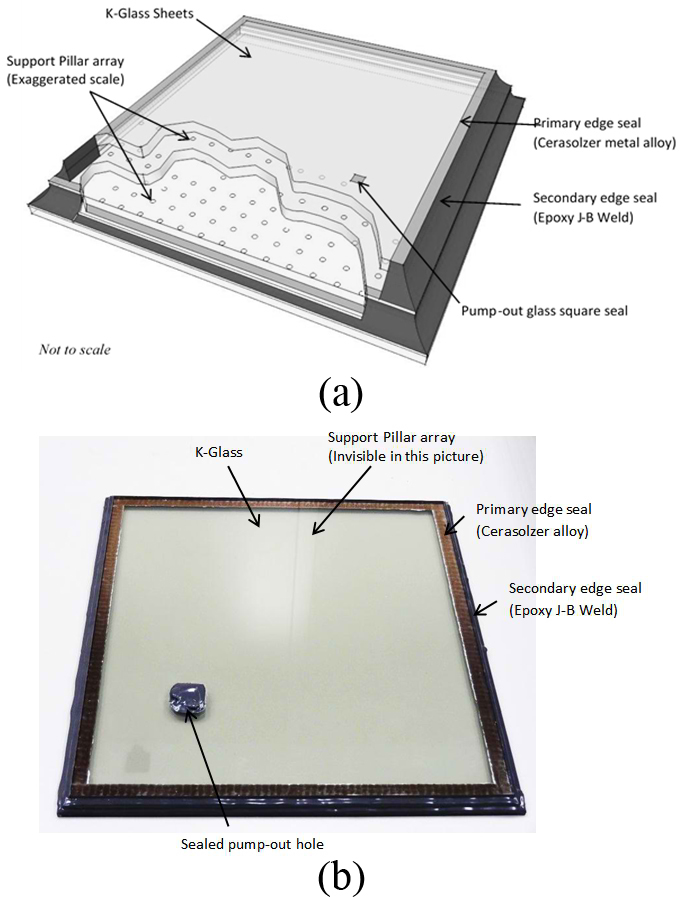

In this paper the achievable U-value of a new fabricated sample of composite edge sealed triple vacuum glazing [20 -22 ] 0.33 Wm-2K-1 is used to predict and analyse the implications on heating energy savings, solar energy gains and heat loss in the UK solid-wall dwelling in comparison to a range of conventional window types, i.e. single glazed, double air glazed, double argon glazed, triple air glazed windows. A composite edge sealed triple vacuum glazing consists of three sheets of tin-oxide (SnO-2 coated k-glass, an airtight seal around the edge of the three glass sheets, and two evacuated cavities at a pressure below 0.1 Pa to decrease heat transfer by gaseous conduction and convection to a negligible level. Radiative heat transfer can further be minimised to a low level by using soft low-emittance coatings, such as silver (Ag) on the surfaces of the glass sheets [16,21 ]. An ordered arrangement of stainless steel support pillars, typically 0.15 mm high and 0.3mm diameter, maintain the separation of the three glass sheets [19 ]. Details of the fabrication and predicted thermal performance are reported elsewhere [21 ] while the sample design is illustrated in Fig. 1 .

Figure 1

Fig. 1. (a) A schematic diagram and (b) fabricated sample photograph of a new low-temperature triple vacuum glazing fabricated with the composite edge seal, made up of Cerasolzer metal alloy and epoxy J-B weld as a primary and a secondary airtight edge seal respectively.

2. Simulation methodology

Existing retrofitting of solid wall dwellings has shown significant advantages of using external wall insulations. In this paper, a detached solid-wall dwelling with brick thick bond with an external insulation was designed and modelled [23] which have a structure of early 20th century located in the Heathrow area of London. The occupancy of this dwelling was modelled to be a family of three adults and one child. The Dimensions of the allocated internal spaces with windows and doors are presented in Table 1, further details of the selection of design parameters are reported elsewhere [24].

Table 1

Table 1. The model dimensions of the allocated internal spaces with windows and doors of a detached solid-wall dwelling.

To predict the comparative performance of triple vacuum glazing with conventional glazing types in a solid-wall dwelling, the dwelling’s fabric must be retrofitted to a minimum 1995 building standard insulations to external solid wall, internal ceiling and floor, loft and ground. The structural U-values used as per 1995 building regulations in the modelled detached solid-wall dwelling are detailed in Table 2.

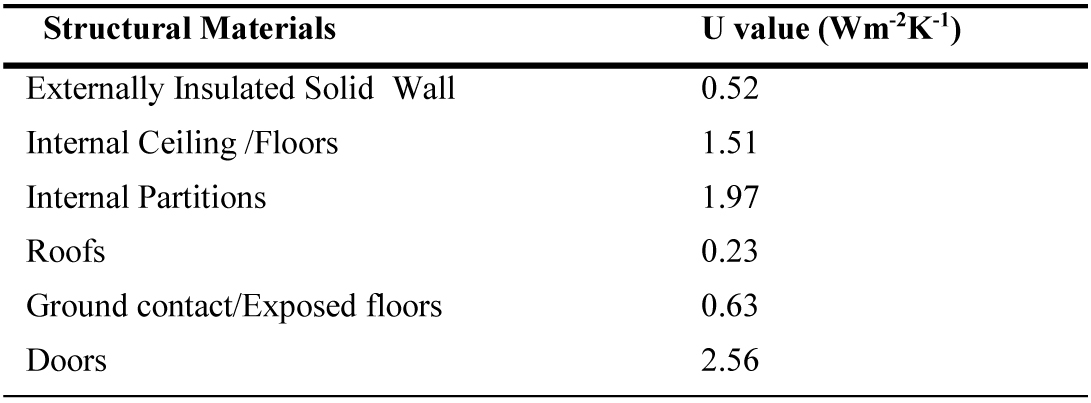

Table 2

Table 2. The structural details with their U-values used in the modelled detached solid-wall dwelling.

The acceptable thermal comfort temperatures for occupants, allowing natural ventilation during summer months, are between 17C and 19C for the winter and summer months as per CIBSE Guide-A standard [25]. In these simulations the set-point temperatures were assigned to be 19°C. A version 4 of ASHRAE weather database was implemented to dynamically run outdoor weather conditions throughout a year. Further details of this 3D dynamic thermal simulation method in which the occupancy, imposed heating regime, natural ventilation and connected infiltration to occupancy, heating and ventilation regimes and internal heat gains are reported elsewhere [24]. The sectional U values of each element was simulated as per standard of CIBSE Guide-A [26] which complies with the BS EN ISO 6946 [27] standard. A conventional frame material PVC was used whilst calculated their effects on overall U-value of windows following EN-ISO standard method. The k-glass used has a visible light transmittance of 0.74, G-value of 0.76 and surface emissivity of 0.9. The model structural details and U values of conventional glazed windows and triple vacuum glazed window are specified in Table 3.

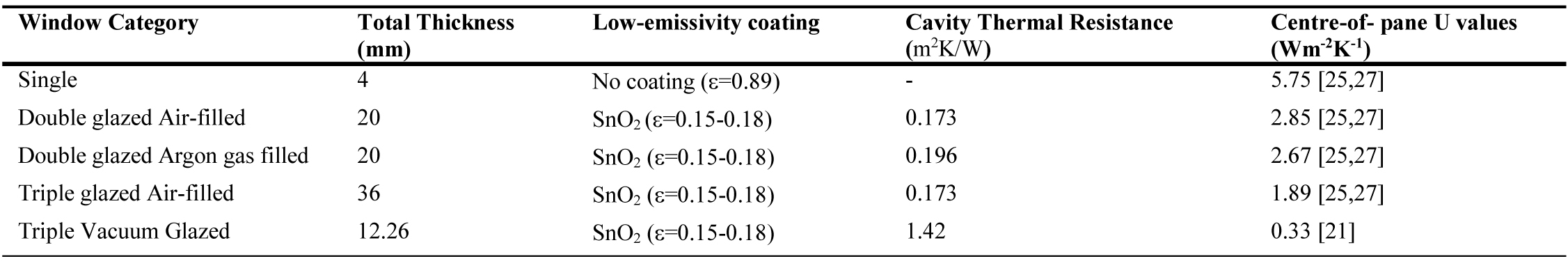

Table 3

Table 3. The model structural details and U values of conventional glazed windows and triple vacuum glazed window.

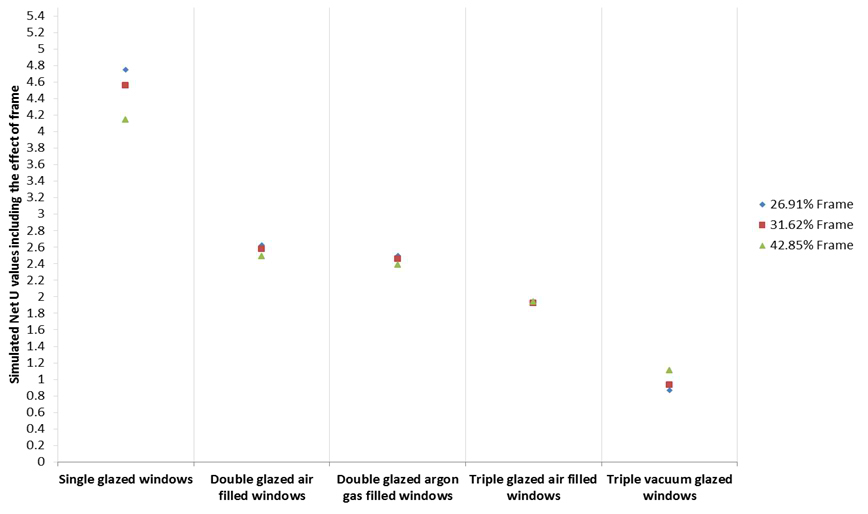

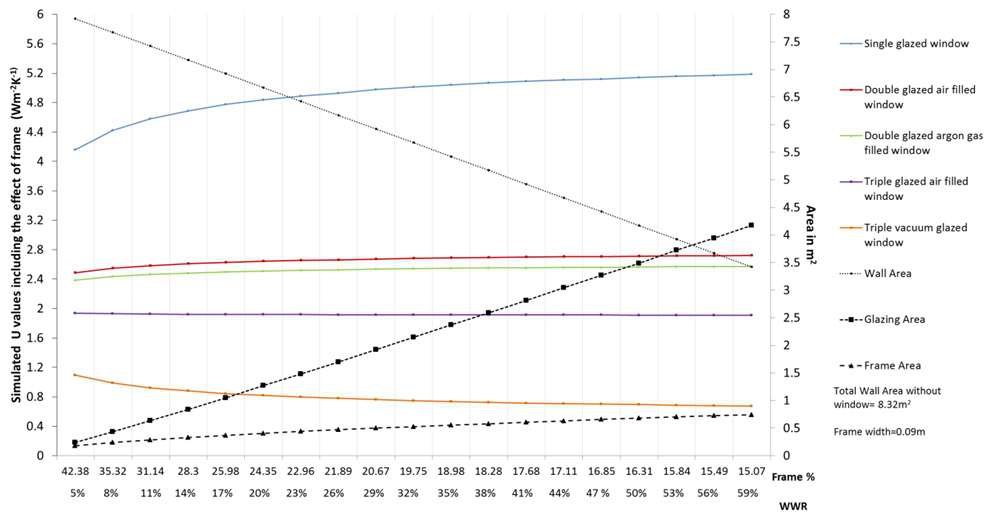

Three different sizes of windows, as detailed in Table 1, were used in the model of the solid-wall detached dwelling with frame areas comprising 26.91%, 31.62%, and 42.85% of the total window area. The calculated window thermal transmittance values (Uw values) used in the simulations are presented in Fig. 2. It can be seen that an increase in the frame percentage of the total window area decreases the value of Uw for single, double air glazed and double argon glazed windows. It is because of the frame thermal transmittance (Uf value) is smaller than that of centre-of-pane thermal transmittance (Ug value). Increasing the frame percentage area of the total window, in the case of triple air glazing, the Uw values calculated were nearly the same to the frame Uf value (i.e. 1.99 Wm-2K-1). In the case of triple vacuum glazed windows, increasing the frame area percentage decreases the Uw values because Ug is much smaller than Uf. Figure 3 illustrates the simulated Uw values for different total window area to total exterior wall space area ratios (WWR) that have different percentages of frame area.

Figure 2

Fig. 2. (a) Calculated net window U values including the effects of frame of the solid wall house model with single, double glazed air filled, double glazed argon gas filled, triple glazed air filled and triple vacuum glazed windows representing the 3 window sizes.

Figure 3

Fig. 3. Calculated net window U values including the effect of frame area and glazing area against different total window area to total exterior wall space area ratios (WWR’s) of a single room (Bedroom 1) in the solid-wall dwelling modelled with single, double air glazed, double argon glazed, triple air glazed and triple vacuum glazed windows.

In the dynamic thermal simulations the above calculated window U values were incorporated to envisage the winter and annual months’ space-heating energy demand. In which the solar heat gains were simulated with an assumption that solar radiation incident on the dwelling surfaces whilst considering direct and diffuse solar radiation perpendicular and horizontal to the plane respectively, which were associated with the version 4 of APACHE weather database [26]. The solar and shading radiation heat transfers were simulated as incident on the glazing. An access of it to the interior of the solid wall dwelling was modelled with the IES Suncast shading data analysis tool [28]. For the annual transmission heat losses through the envelope and ventilation heat losses, steady-state calculation methods have been applied details are reported elsewhere [29].

3. Results and Discussion

The dynamic building thermal model predictions of the space-heating energy demand and solar energy gains for the winter and summer months are briefed below. The comparative cost and energy savings are presented. An integrated heat flow performance, of dwelling with different window types has been carried out, is also presented.

3.1 The space- heating degree day analysis

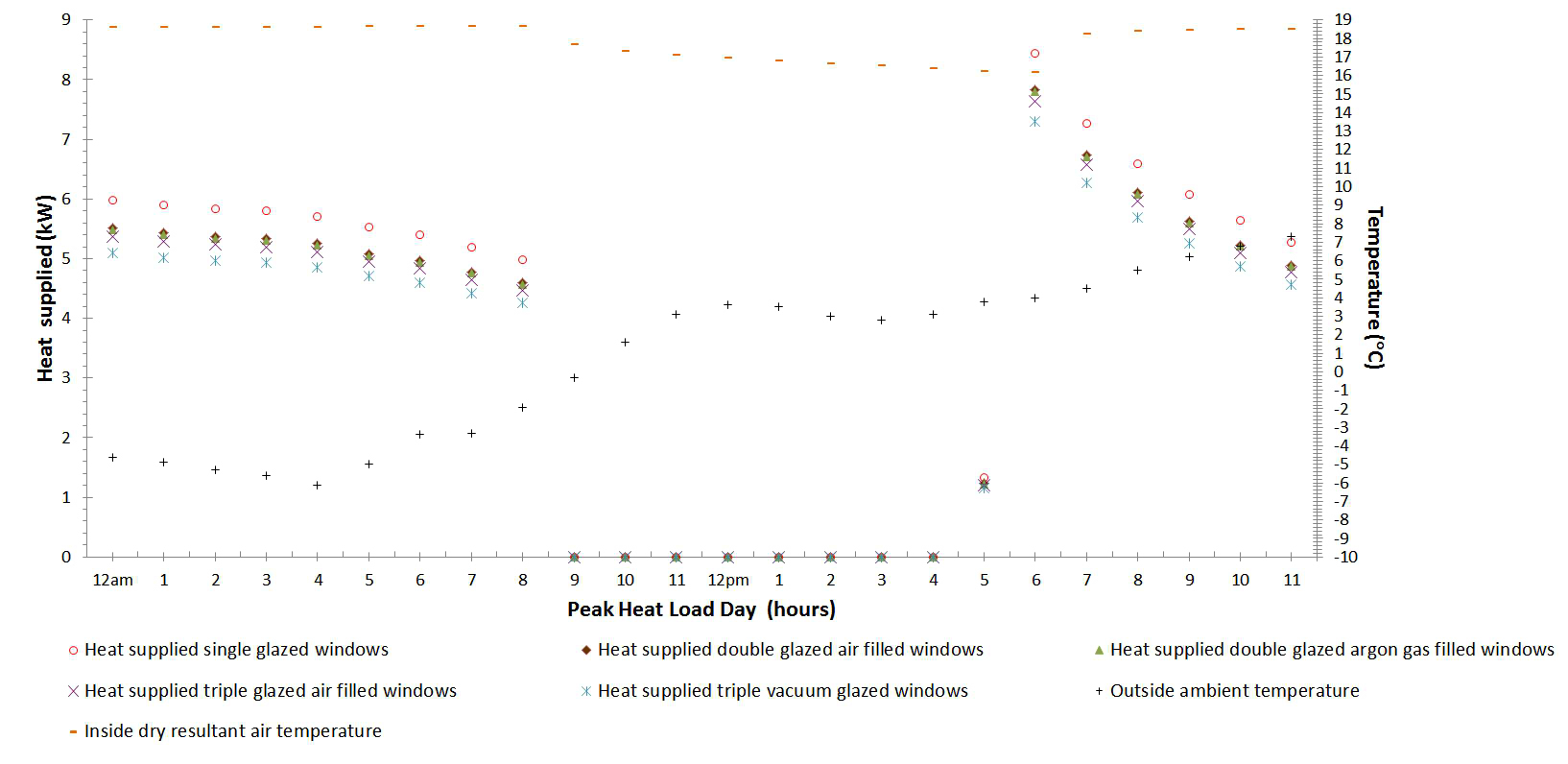

The space-heating degree day analysis has been carried out on a day of high space-heating supply to envisage the peak energy performance of a solid-wall dwelling modelled with triple vacuum glazed windows compared to triple air glazed, double argon glazed, double air glazed and single glazed windows. However, the simulations were run at a time step of one minute and data collection every one hour. It was noticed the highest heat supply demand was predicted on 29th of December. This is due to lower values of weather temperatures on this winter month. It should be noted that on this working day (Tuesday) an occupancy regime was set that the dwelling was occupied by: 4 households (6-8 pm); 1 household (8-3 pm); and 2 households (3-6 pm). This was related to the heating and the ventilation profiles and accounts internal heat gains and heat loss due to the infiltration. However, the inside heating supply set-point temperatures of all of the rooms were set to 19C. Figure 4 compiles predicted indoor air-temperatures and heat supplied to five dwellings, each retrofitted with different glazed window types.

Figure 4

Fig. 4. (a) The predicted indoor air-temperatures and heat supplied to five dwellings, each retrofitted with different glazed windows, showing the comparative performance of triple vacuum glazed and conventional glazed windows.

Figure 4 illustrates the space-heating degree day simulated results over the period of 24 hours on a day of high heat supply to maintain thermal comfort temperatures. The reason, it required high heat supply, is due to the lower outside weather temperatures i.e. approximately between 1.5C and 7C. In which the dwelling with triple vacuum glazed windows consumed less space-heating compared to the other types of glazed windows. Between 12 am and 8 am the heat supply was turned on, because the dwelling was fully occupied by the households. Though the heating system was non-operational from 8 am to 6 pm in which, it can be seen, the inside air temperature was slightly lower than the set-point temperature i.e. around 16C. When the heating system was operational from 6pm, a rise of heat supply was noticed. However, this rise of the heat supply was less with the dwelling of triple vacuum glazed windows compared to the dwelling with other glazed windows. For example, the calculations show, a reduction of 4.8%, 6.7%, 7.2%, and 14.4% of heat supply for the dwelling with triple vacuum glazed windows when compared to the dwelling with triple air glazed, double argon glazed, double air glazed and single glazed windows respectively.

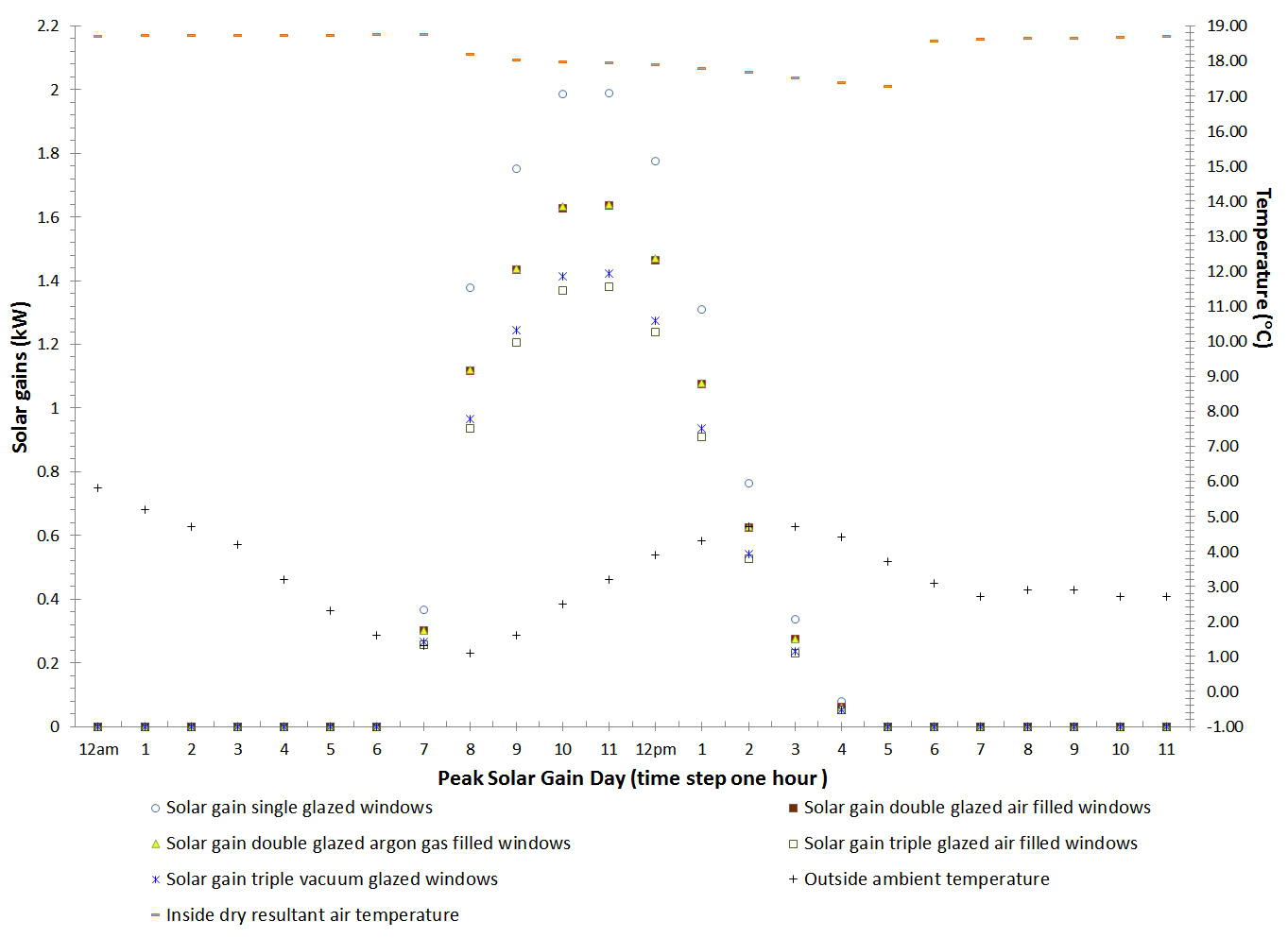

3.2 The Peak day solar gain analysis

For the clear interpretation of the comparative advantages of triple vacuum glazings with other glazing types, a day from the simulations and weather database was picked when the sunlight penetration is high to the dwelling fabric i.e. around noon on 14-Feb. This is because daylighting hours fluctuate in the UK and it was necessary to have a period of continuous daylighting for a particular period of time. It can be seen from Fig. 5 the solar gains are slightly higher in the dwelling with single glazed windows compared to other types of glazed windows including triple vacuum glazed windows. On the other hand, during summer months such solar gains can cause overheating and for this reason in the London and most parts of the UK the low-emittance coated double air glazed windows are recommended minimum to the dwelling. Though the simulated results achieved an important likewise comparison, as shown in Fig. 5, the solid-wall dwelling with triple vacuum glazed windows have slightly higher solar gains (i.e. 1.64 kW) than the solid-wall dwelling with triple air glazed windows (i.e. 1.38 kW). It is due to the thinness of the triple vacuum glazing because two evacuated cavities gap is 0.26mm thick, as compared to 24 mm air cavities gap of triple air glazed windows. However, keeping the visible light transmittance to 0.74 is one of the key characteristic of triple vacuum glazing.

Figure 5

Fig. 5. (a) The predicted peak day solar gains to the solid wall dwellings with triple vacuum glazed windows and the other types of glazed windows.

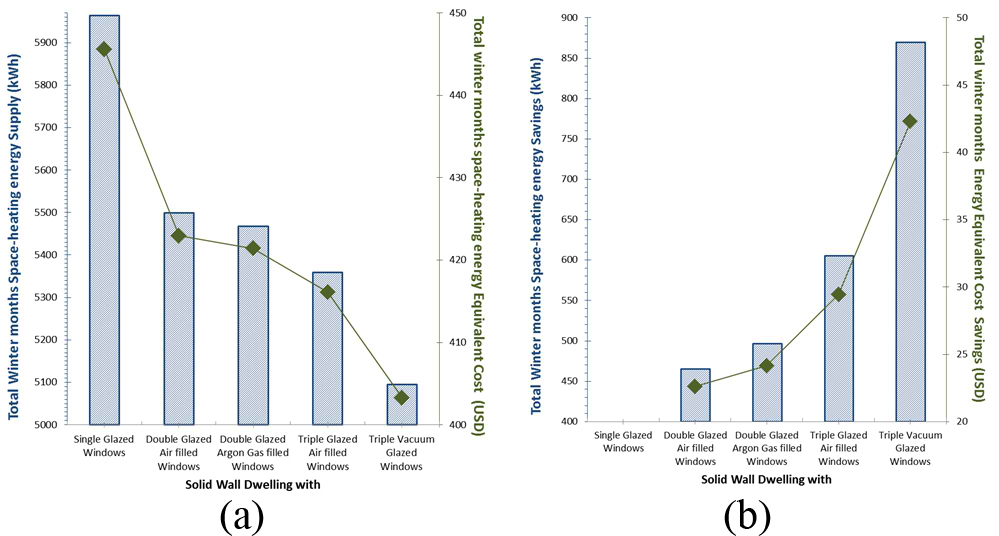

3.3 Predictions of the Annual and winter months Energy Cost Savings

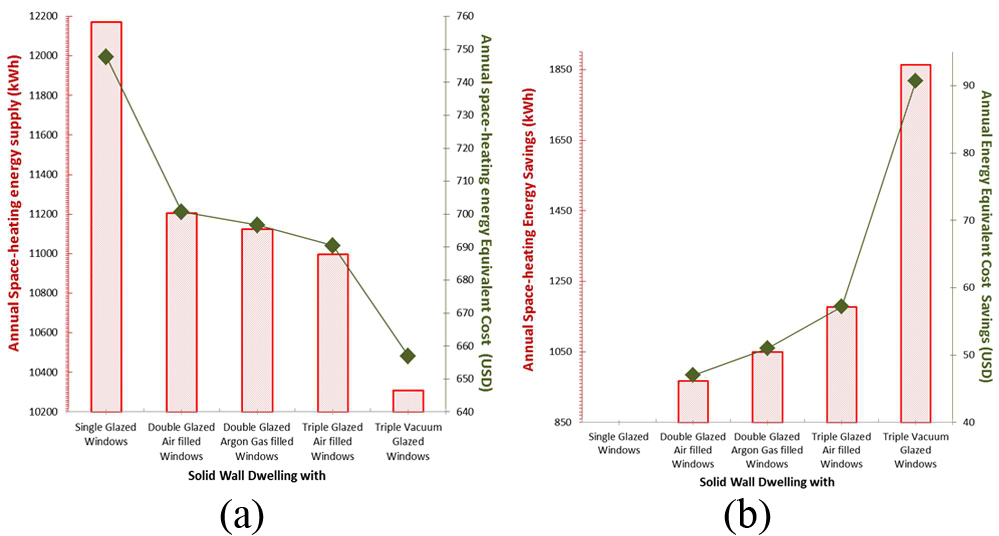

In order to maintain the thermal comfort temperatures, as set out 19°C in the methodology with rational regimes, the Low-Temperature-Hot-Water boiler type was used in the simulations. The space-heating energy cost calculations were based on the British Gas Standard Tariff for the London, Heathrow area i.e. 0.11 USD for first 2680 kWh units and then 0.05 USD per kWh) [30]. Although an accurate gas tariff varies as per the method of setting up the payments and/or direct debits [5]. It can be seen from Fig. 6(a) the total winter months (Dec, Jan, and Feb) space-heating energy supplied, its subsequent equivalent cost in USD, and Fig. 6(b) shows its savings compared to a solid wall dwelling with single glazed windows. A notable space-heating energy savings of around 14.58% (USD 42.3) was obtained with a solid-wall dwelling retrofitted with triple vacuum glazed windows when compared to single glazed windows. It is debatable, yet to know, a slight savings of around 7.35% (USD 12.9) was obtained with triple vacuum glazed windows compared to triple air glazed windows for the month of Dec, Jan and Feb. However, as discussed earlier, advantages of triple vacuum glazing can also be realized with its thinness that would save frame material and as proposed in Memon (2013) [22] the use of cost-effective materials add the overall fabrication and energy cost savings.

Figure 6

Fig. 6. Total winter months (a) space-heating energy supply and (b) its equivalent cost savings in USD of the simulated solid-wall dwelling retrofitted with different glazings.

By running the simulations of annual months along with the annual dynamic weather profile; the total space-heating energy savings of around 15.31% (equivalent USD 90.7) were acquired when a solid-wall dwelling substitute’s single glazed windows for triple vacuum glazed windows as shown in Fig. 7(a) and Fig. 7(b). A sharp increase of savings can be seen in the annual analysis (Fig. 7(b)). The savings can be more appreciable when the solid-wall insulation is improved to 2010 UK building regulations. Simulated results show an insignificant space-heating and cost savings with double argon glazed windows compared to double air glazed windows. Solar gains do contribute in reducing the space-heating load but during summer months it could cause overheating and may be inconvenient to households and cooling is necessary in this case. In this research work, natural purge ventilation profiles were created and simulated as the only cooling method.

Figure 7

Fig. 7. (a) Annual space-heating energy supply and (b) its equivalent cost savings in USD of the simulated solid-wall dwelling retrofitted with different glazed windows.

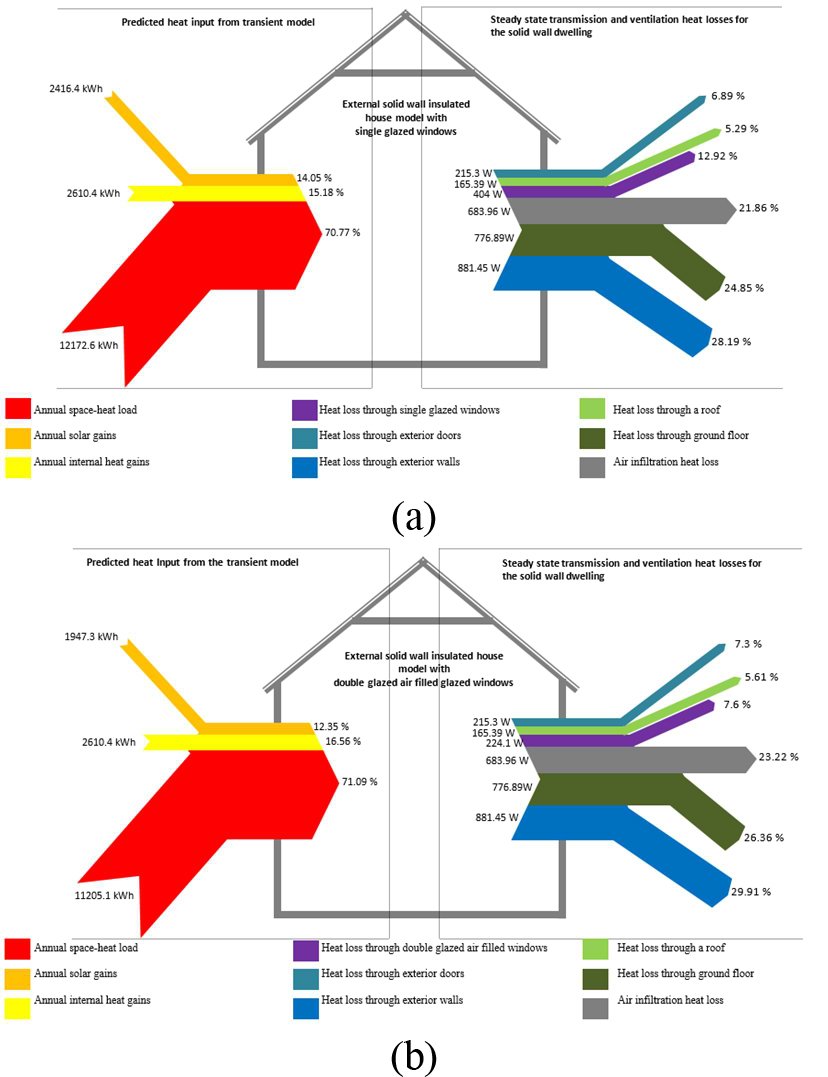

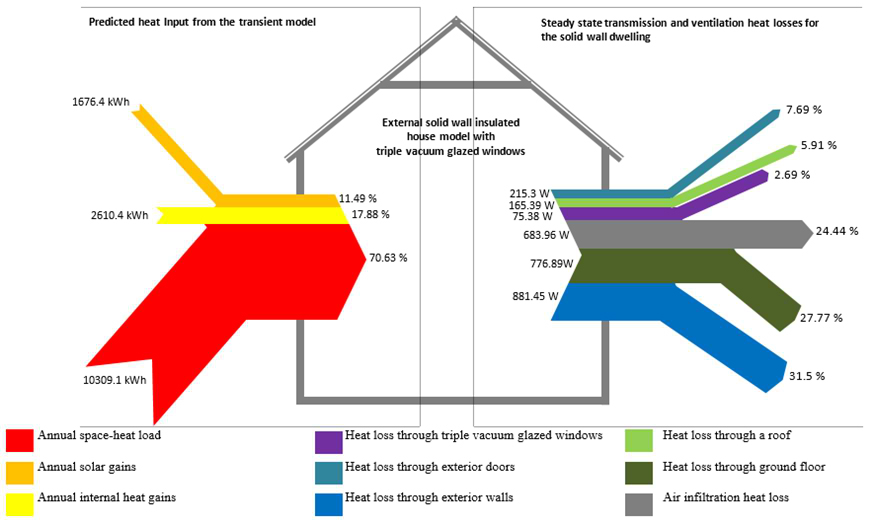

3.4 Analysis of changes in heat flows

The dynamic thermal modelling results of heat supplied and steady state heat loss calculations were integrated to analyse the changes in heat flows for the solid-wall dwelling with different window systems. The steady state calculations predict 12.92%, 7.6%, 7.26%, 5.71%, and 2.69% of heat loss for the solid-wall dwelling with single glazed, double air glazed, double argon glazed, triple air glazed and triple vacuum glazed windows respectively, as shown in Figs. 8-10. By keeping all the heat losses through the dwelling fabric into consideration, this gives the heat loss saving of 10.23% to the solid-wall dwelling with triple vacuum glazed windows (Fig. 10) when compared to the solid-wall dwelling with single glazed windows (Fig. 8(a)). The steady state heat loss through ventilation/infiltration can be seen to account for 21.86%, 23.22%, 23.29%, 23.67%, and 24.44% of the heat loss for the solid-wall dwelling with single, double air glazed, double argon glazed, triple air glazed and triple vacuum glazed windows. In overall, the percentage of heat loss was minimised with the retrofit of triple vacuum glazed windows, as shown in Fig. 10. A larger percentage of the heat loss was resulted from the exterior walls. This heat loss can be minimized when improving the external wall insulation and adequately minimising the air leakage through the solid-wall dwelling envelope whilst allowing the moisture vapour from the house to safely evaporate into the outside air to avoid interstitial condensation.

Figure 8

Fig. 8. Heat flow diagram for an external solid wall insulated dwelling with (a) single and (b) doubled glazed windows. Simulated heat input from a dynamic model and steady state transmission heat losses through the envelope and by air infiltration.

Figure 9

Fig. 9. Showing heat flow diagram for an external solid wall insulated dwelling with (a) double glazed argon gas (b) triple glazed air filled windows.

Figure 10

Fig. 10. Illustrating heat flow diagram for an external solid wall insulated dwelling with triple vacuum glazed windows.

4. Conclusions

A model for a domestic dwelling of four households with external solid-wall insulation was developed in order to investigate the space-heating loads and solar gains with the use of different glazing systems. In these simulations, the achievable thermal transmittance (U-value) of a new composite edge-sealed triple vacuum glazing was modelled i.e. 0.33 Wm-2K-1. In the space-heating degree day analysis, a peak energy reduction of 4.8%, 6.7%, 7.2%, and 14.4% of heat supply for the dwelling with triple vacuum glazed windows when compared to the dwelling with triple air glazed, double argon glazed, double air glazed and single glazed windows was predicted respectively. A notable total winter months space-heating energy savings of around 14.58% (USD 42.3) was obtained with a solid-wall dwelling retrofitted with triple vacuum glazed windows when compared to single glazed windows. However, a slight savings of around 7.35% (USD 12.9) was obtained with triple vacuum glazed windows compared to triple air glazed windows for the month of Dec, Jan and Feb. The total annual space-heating energy savings of around 15.31% (equivalent USD 90.7) were acquired when a solid-wall dwelling substitute’s single glazed windows for triple vacuum glazed windows, shows a prominent increase of savings. However, the space-heating energy cost savings can be more appreciable when the solid-wall insulation is improved to 2010 building regulations. Simulated results show an insignificant space-heating and cost savings with double argon glazed windows. Solar gains do contribute in reducing the space-heating load but during summer months it could cause overheating and may be inconvenient to households and cooling is essential in such circumstances. Thus, the triple vacuum glazing, if manufactured at the mass production level with cost-effective airtight sealing materials and improved fabrication methods, is a great opportunity in reducing building energy consumption and has a potential to increase window-to-wall area ratios for more solar gains, specifically in the cold arid climates.

Acknowledgements

This research work was performed at Loughborough University and was funded by the EPSRC UK (EP/G000387/1). The corresponding author likes to thank Loughborough University and the project CALEBRE partners for support on conducting this research. Permission to implement British Standards in thermal modelling is granted by BSI.

Contributions

S. Memon conducted the research under the supervision of P.C. Eames. P. C Eames has contributed with ideas and the quality of analysis. All authors contributed to the refinement of the study and improved the final manuscript.

References

- C. Breidenich, D. Magraw, A. Rowley and J. W. Rubin, The Kyoto Protocol to the United Nations Framework Convention on Climate Change, The American Journal of International Law 92 (1998) 315-331.

- A. L. Bristow, M. Tight, A. Pridmore, and A. D. May, Developing pathways to low carbon land-based passenger transport in Great Britain by 2050, Energy Policy 36 (2008) 3427-3435. http://dx.doi.org/10.1016/j.enpol.2008.04.029

- HMG, Climate Change Act 2008, HMSO 12 (2008) 415435-19585.

- J. G. Rogers, S. J. G. Cooper, A. O. Grady, M. C. McManus, H. R. Howard, and G. P. Hammond, The 20% house – An integrated assessment of options for reducing net carbon emissions from existing UK houses, Applied Energy 138 (2015) 108-120.

- R. M. Cuéllar-Franca and A. Azapagic, Environmental impacts of the UK residential sector: Life cycle assessment of houses, Building and Environment 54 (2012) 86-99. http://dx.doi.org/10.1016/j.buildenv.2012.02.005

- V. Cheng and K. Steemers, Modelling domestic energy consumption at district scale: A tool to support national and local energy policies, Environmental Modelling & Software 26 (2011) 1186-1198. http://dx.doi.org/10.1016/j.envsoft.2011.04.005

- Y. Xing, N. Hewitt, P. Griffiths, Zero carbon buildings refurbishment––A Hierarchical pathway, Renewable and Sustainable Energy Reviews 15 (2011) 3229-3236. http://dx.doi.org/10.1016/j.rser.2011.04.020

- B. Petter Jelle, A. Hynd, A. Gustavsen, D. Arasteh, H. Goudey, R. Hart, Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities, Solar Energy Materials and Solar Cells 96 (2012) 1-28. http://dx.doi.org/10.1016/j.solmat.2011.08.010

- N. Hamza and R. Gilroy, The challenge to UK energy policy: An ageing population perspective on energy saving measures and consumption, Energy Policy 39 (2011) 782-789. http://dx.doi.org/10.1016/j.enpol.2010.10.052

- M.R. Gaterell and M.E. McEvoy, The impact of climate change uncertainties on the performance of energy efficiency measures applied to dwellings, Energy and Buildings 37 (2005) 982-995. http://dx.doi.org/10.1016/j.enbuild.2004.12.015

- P. Banfill, S. Simpson, V. Haines, and B. Mallaband, Energy‐led retrofitting of solid wall dwellings: Technical and user perspectives on airtightness, Structural Survey 30 (2012) 267–279. http://dx.doi.org/10.1108/02630801211241829

- V. Haines and V. Mitchell, A persona-based approach to domestic energy retrofit, Building Research & Infortmation 42 (2014) 462-476. http://dx.doi.org/10.1080/09613218.2014.893161

- A.Peacock, P. C. Eames, H. Singh, T. J. Berry, P. F. Banfill, S. Turan, D. Jenkins, M. Ahadzi, G. Bowles, D. Kane, M. Newborough. Reducing CO2 emissions through refurbishment of UK housing, In: ECEEE Summer Study. Saving Energy-Just do It, 2007, pp. 951-962, France.

- D. Johnston, R. Lowe, and M. Bell, An exploration of the technical feasibility of achieving CO2 emission reductions in excess of 60% within the UK housing stock by the year 2050, Energy Policy 33 (2005) 1643-1659. http://dx.doi.org/10.1016/j.enpol.2004.02.003

- D.P. Jenkins, The value of retrofitting carbon-saving measures into fuel poor social housing, Energy Policy 38 (2010) 832-839. http://dx.doi.org/10.1016/j.enpol.2009.10.030

- P. C. Eames, Vacuum glazing: Current performance and future prospects, Vacuum 82 (14) 717-722. http://dx.doi.org/10.1016/j.vacuum.2007.10.017

- R.E. Collins and T.M. Simko, Current status of the science and technology of vacuum glazing, Solar Energy 62 (1998) 189-213. http://dx.doi.org/10.1016/S0038-092X(98)00007-3

- W. Wuethrich. Heat reducing closure element, Eur Pat No. 1529921, 2005.

- Y. Fang, T. J. Hyde, and N. Hewitt, Predicted thermal performance of triple vacuum glazing, Solar Energy 84 (2010) 2132-2139. http://dx.doi.org/10.1016/j.solener.2010.09.002

- S. Memon and P. C. Eames, An investigation on edge sealing materials for the fabrication of vacuum glazing, In: 3rd School of Electrical, Electronic and Systems Engineering (EESE) Research conference, 2013, UK.

- S. Memon, F. Farukh, P. C. Eames, and V. V. Silberschmidt, A new low-temperature hermetic composite edge seal for the fabrication of triple vacuum glazing, Vacuum 120 (2015) 73-82. http://dx.doi.org/10.1016/j.vacuum.2015.06.024

- S. Memon, Design, fabrication and performance analysis of vacuum glazing units fabricated with low and high temperature hermetic glass edge sealing materials, PhD Thesis, Loughborough University Institutional Repository, UK, 2013. https://dspace.lboro.ac.uk/2134/14562

- P. Lofthouse, The development of English semi-detached dwellings during the nineteenth century, Institute of Archaeology PIA 22 (2012) 83-98. http://dx.doi.org/10.5334/pia.404

- S. Memon, Analysing the potential of retrofitting ultra-low heat loss triple vacuum glazed windows to an existing UK solid wall dwelling. Int. Journal of Renewable Energy Development 3 (2014) 161-174. http://dx.doi.org/10.14710/ijred.3.3.161-174

- CIBSE, Guide-A Environmental Design. (7th ed.), The Chartered Institution of Building Services Engineers, London, 2006.

- IES-ASHRAE, ASHRAE weather database version 4.0. APLocate User Guide. ASHRAE. Accessed: August 2015, Available at: www.iesve.com/content/downloadasset_2878.

- BS EN ISO 6946, Building components and building elements-Thermal resistance and thermal transmittance-Calculation method, British Standard, 2007.

- IES-VE, Dynamic Thermal Modelling Software version 6.4.0.10, Integrated Environmental Solutions, 2012.

- S. Memon. Investigating energy saving performance interdependencies with retrofit triple vacuum glazing for use in UK dwelling with solid wall, In: Proceedings of the 7th International Conference on Sustainable Development on Building and Environment, Reading, UK, 2015.

- I.A. Grant Wilson, A. J.R. Rennie, Y. Ding, P. C. Eames, P. J. Hall, and N. J. Kelly, Historical daily gas and electrical energy flows through Great Britain's transmission networks and the decarbonisation of domestic heat, Energy Policy 61 (2013) 301-305. http://dx.doi.org/10.1016/j.enpol.2013.05.110

Copyright © 2017 The Author(s). Published by solarlits.com.

HOME

HOME Figure 1

Figure 1 Table 1

Table 1 Table 2

Table 2 Table 3

Table 3 Figure 2

Figure 2 Figure 3

Figure 3 Figure 4

Figure 4 Figure 5

Figure 5 Figure 6

Figure 6 Figure 7

Figure 7 Figure 8

Figure 8 Figure 9

Figure 9 Figure 10

Figure 10