Article outline

Figures and tables

Volume 1 Issue 1 pp. 29-35 • doi: 10.15627/jd.2014.4

Maximizing the Performance of Laser Cut Panel by Interaction of Ceiling Geometries and Different Aspect Ratio

Author affiliations

College of Architecture and Design, Jordan University of Science and Technology, Irbid 22110, Jordan.

* Corresponding author. Tel.: +962 0772049713

E-mail addresses: aafreewan@just.edu.jo, ahmedfreewan@hotmail.com

History: Received 20 September 2014 | Revised 27 October 2014 | Accepted 20 November 2014 | Published online 22 December 2014

Copyright: © 2014 The Author(s). Published by solarlits.com. This is an open access article under the CC BY license (http://creativecommons.org/licenses/by/3.0/).

Citation: Ahmed A. Freewan, Maximizing the Performance of Laser Cut Panel by Interaction of Ceiling Geometries and Different Aspect Ratio, Journal of Daylighting 1 (2014) 29-35. http://dx.doi.org/10.15627/jd.2014.4

Figures and tables

Abstract

The interaction between different ceiling geometries with laser cut panels (LCPs) is investigated using real experiments and computer simulations to maximize the daylight performance of the LCP. In addition, LCP with different aspect ratios (width to depth ratio) is studied using simulation with clear sky conditions in hot climate region. Two main performance parameters are investigated: illuminance level and distribution uniformity in a large space located in a sub-tropical climate region like Jordan. It was found that curved and chamfered ceilings increased the daylight level in the rear part of the studied room by 20% compared to a horizontal flat ceiling and reduce it by 30% in front part that improve the quality of daylight by improving the uniformity. LCP with high aspect ratio of 5:6 performed well in climate with clear sky and high solar angles than LCP with ratio of 4:6.

Keywords

Laser cut panel; Illuminance level; Uniformity; Ceiling geometry

1. Introduction

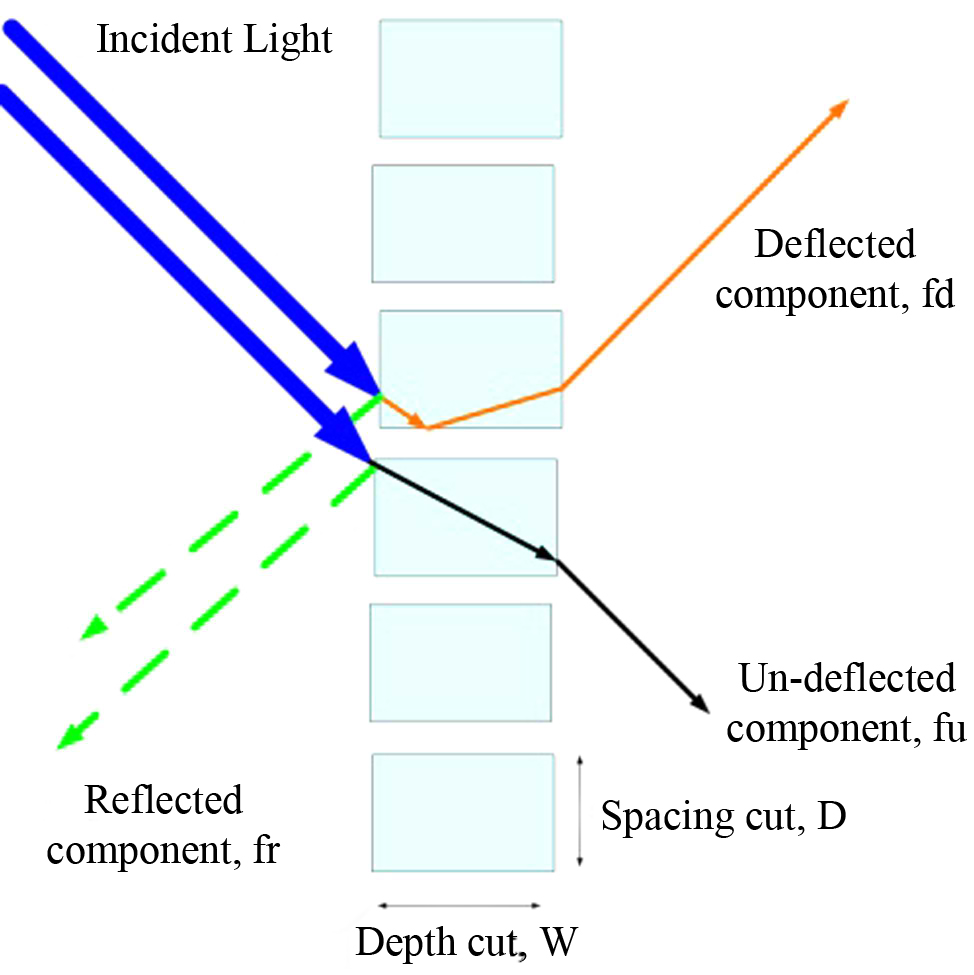

A laser cut panel (LCP) is an innovative daylighting system used to redirect high angle lights upwards towards the ceiling by total interior reflection (TIR), while it redirects low angle light or diffuse light downwards by internal refractions. In 1898, Wadsworth invented the concept of forming arrays of reflectors inside transparent glazing, but it was not known until 1988 to make a linear cutting inside the glazing. The practical method of producing a light directing panel using LCP was invented in 1988, and the optical theory of LCP was developed and become available with easiness in manufacturing in 1993 [1,2]. LCP is an optical material produced by making fine parallel laser cuts in a thin panel of clear acrylic material [1,2]. The fractions of these components depend on the cut-depth to cut-spacing ratio and the incident angle of sunlight [3–6]. LCP reflects more light deeply through a large angle (>120), which can increase the light level by 10–30%. In the case of high sun rays (>30), the deflected components will be the main components, while in cases of low angle, un-deflected components will be the main ones. Therefore, the LCP will reflect summer sun rays upwards while allowing winter sun rays to pass through as un-deflected components.

The performance of the LCP depends on the aspect D:W ratio, the ratio of depth of cut to the space between cuts, and panel tilt angle. It can be mounted as primary glazing or as a secondary internal glazing in the upper part of a window to perform the same function as a light shelf.

In [7,8], they provided the main characteristics of LCPs: 1) simple to install as hung windows or structurally fixed, and can be external or internal inside double glazing sheets 2) applied to avoid glare and heat gain 3) powerful daylighting device, which can also provide shading 4) maintain the outside view 5) flexibility in manufacturing 6) effective in east and west elevations and reject around 70% of east and west rays in summer 7) free maintenance.

In [2], they investigated the potential of LCPs to increase the daylight level in lower spaces of a high-rise building in a high-density area. They studied the effect of tilt angle and cut angle versus the incident angle. The study showed that manipulating tilt angles and cut angles of the LCP can maximize its ability to reflect more daylight deep into spaces. LCP increased the light level at the back of the space in an area with very low daylight while reducing it near the window; thus, it improved illuminance uniformity.

LCPs were used to increase daylight in lower rooms in high-density residential buildings [7]. The study was based on physical model experiments with an obstruction angle of 70°. The study showed that the daylight level can be increased in the rear part up to three times using tilted out LCPs.

In [3], they studied enhancement of illuminance level inside greenhouses in a high latitude climate using double glazing comprising a LCP. The device was demonstrated under both diffuse and clear skies. The results showed that LCPs are more effective than other systems. In high latitude (>50°), the enhancement approached to 100% under a clear sky.

Greenup and Edmonds developed an algorithm to simulate a LCP in Radiance (Section 2.3). The algorithm helped to study and test more variables relevant to the laser cut. Therefore, it is used in the current research to optimize the LCP’s performance.

In Fig. 1, it is shown that how the LCP works, and three types of ray redirection occur in LCPs that are deflected components, un-deflected components, and reflected off components.

Different studies [9–12] investigated how the ceiling geometries improved the daylight performances of redirecting daylight devices like light shelve and louvers. In [13], they studied the importance of ceiling geometers from daylight point of view and developed an algorithm for architects that aids in generation and finding of curvilinear and mesh ceiling forms. The study used the ceiling shapes to improve daylight performance of buildings. Other study explored how wall geometers improved the daylight performance of the courtyard in hot climate region [14].

The remainder of the paper is organized in the following manner. Section 2 describes experimental setup and simulation setup using Radiance for the LCP. The results from experiments and simulation are presented in Section 3 where different ceiling geometries are used. Finally, brief concluding remarks are included in Section 4.

2. Methods

2.1. Experimental setup

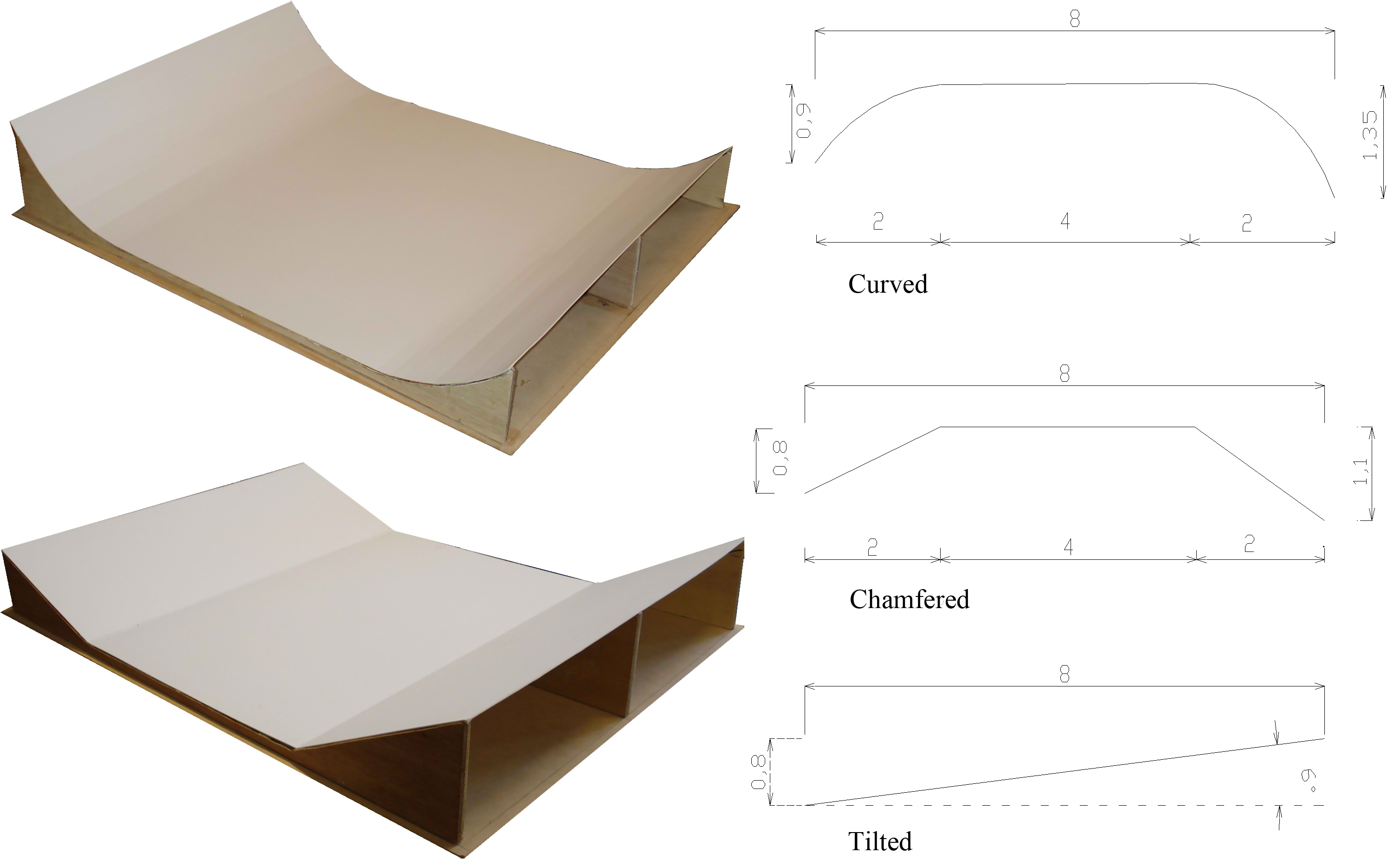

Experiments were conducted in Irbid-Jordan (32.55 N, 35.9 E) to assess the role of ceiling geometries on the daylighting performance of the model. A final and improved model setting was used to study the performance of LCP systems under real sky conditions. To examine the effect of ceiling geometries on the performance of LCP, two models scale (1:10) were constructed. The dimensions of the simulated room were 8 m long, 3 m wide, and 3.25 m high. The first model considered as a reference case (i.e. a room served by LCP with horizontal ceiling), while the second model considered as an experiment case (i.e. a room served by one of the LCP with shaped ceiling: curved or chamfered ceiling). The ceilings, walls, and floors were constructed using materials with reflectance 80%, 65%, and 45%, respectively. Each model had a window facing south of 30 cm high and 20 cm wide. The window had a sill of 90 cm high and a glazing of 85% transmittance. The distance that used to shape the ceiling in the front part of the curved or chamfered ceiling was subsequently used as a reference point for the back part.

Curved ceiling, as shown in Fig. 2, is a ceiling that is curved in the front and back parts. Front part started directly above the window and extended 2 m horizontally. Chamfered ceiling, as shown in Fig. 2, is a ceiling that has sloped part at the front and the back parts. The start and end points of the sloped part are the same as those used for curved ceiling. A rectangular LCP 20×30 cm with 4:6 width to depth ratio was used in each model.

2.2. Room simulation setup

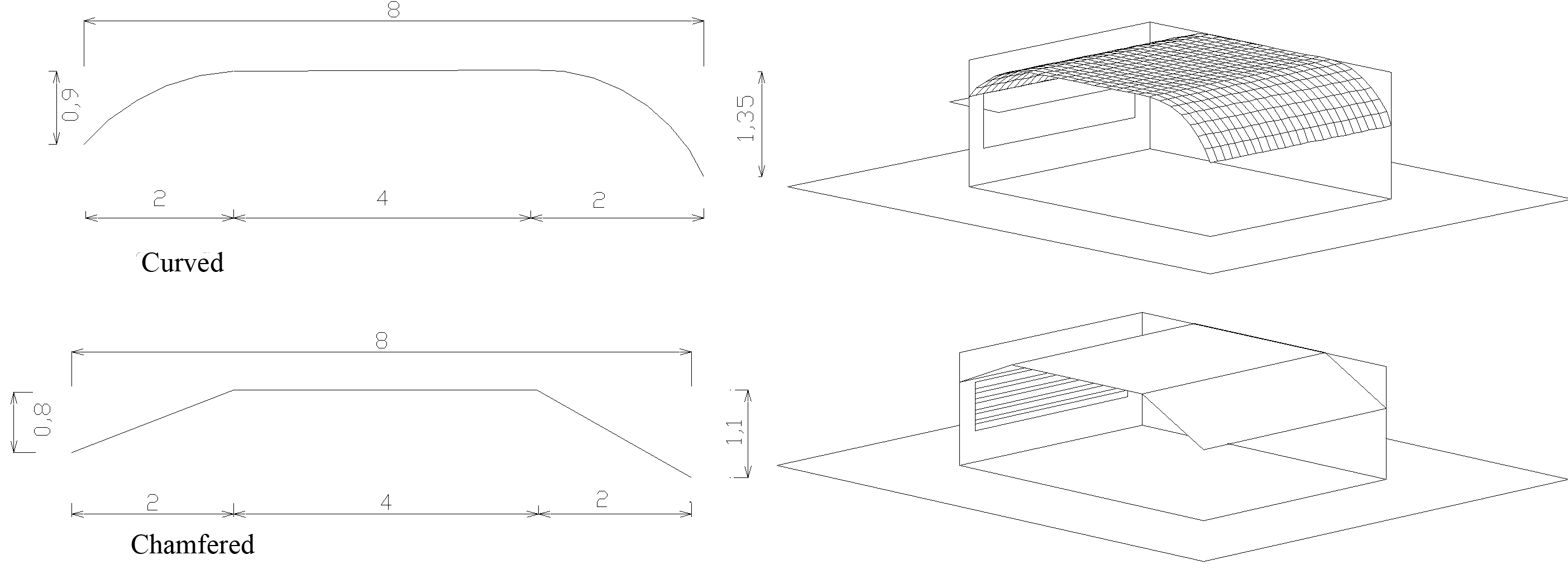

The ceiling geometries adopted in the experiments were modeled and examined using AutoCAD and Radiance. Exact models of rooms, ceiling geometries, and windows, were modeled in AutoCAD, as shown in Fig. 3. Materials, with reflectance properties like those mentioned in experiments, were applied to the surfaces. These models were simulated in the same experimental period from 10 am to 4 pm in May. Models were simulated under clear sky condition with sun for Irbid city in Jordan (32.55 N, 35.9 E).

2.3. Radiance

Radiance is a highly capable lighting simulation program [15]. Color visual representation of a room is possible in it, and the most important prediction of luminance values can be easily done in Radiance. Due to its exceptional flexibility, Greenup and Edmonds [15] considered Radiance one of the most highly capable lighting simulation programs currently available. In [16–18], they showed good agreement between results from Radiance and actual results for clear glazing, louvers, and light shelves under identical sky conditions. In [17,18], they demonstrated that Radiance is highly agreed with real result as long as the sky condition well identified. Radiance has been validated by different researchers in different cases, and obtained results have been found to be in good agreement with experimental measurements [19–22].

Algorithm in [1] was used to model the LCP in Radiance. The algorithm was developed to effectively model the devices in Radiance for improving lighting simulation. The algorithm described the light behavior within the LCPs depending on the width to depth ratio (W:D). According to the algorithm, Radiance process three types of rays: deflected, un-deflected, and reflected [5]. The simulation process of LCP is as follows: 1) model the room using AutoCAD including a window and add proper material to the surfaces 2) Simulate the model using Radiance 3) Change the window’s material to LCP parameter by changing the material properties in the Radiance material library 4) Call the calculation file, which is developed by Greenup and Edmond.

3. Results

3.1. Experiments

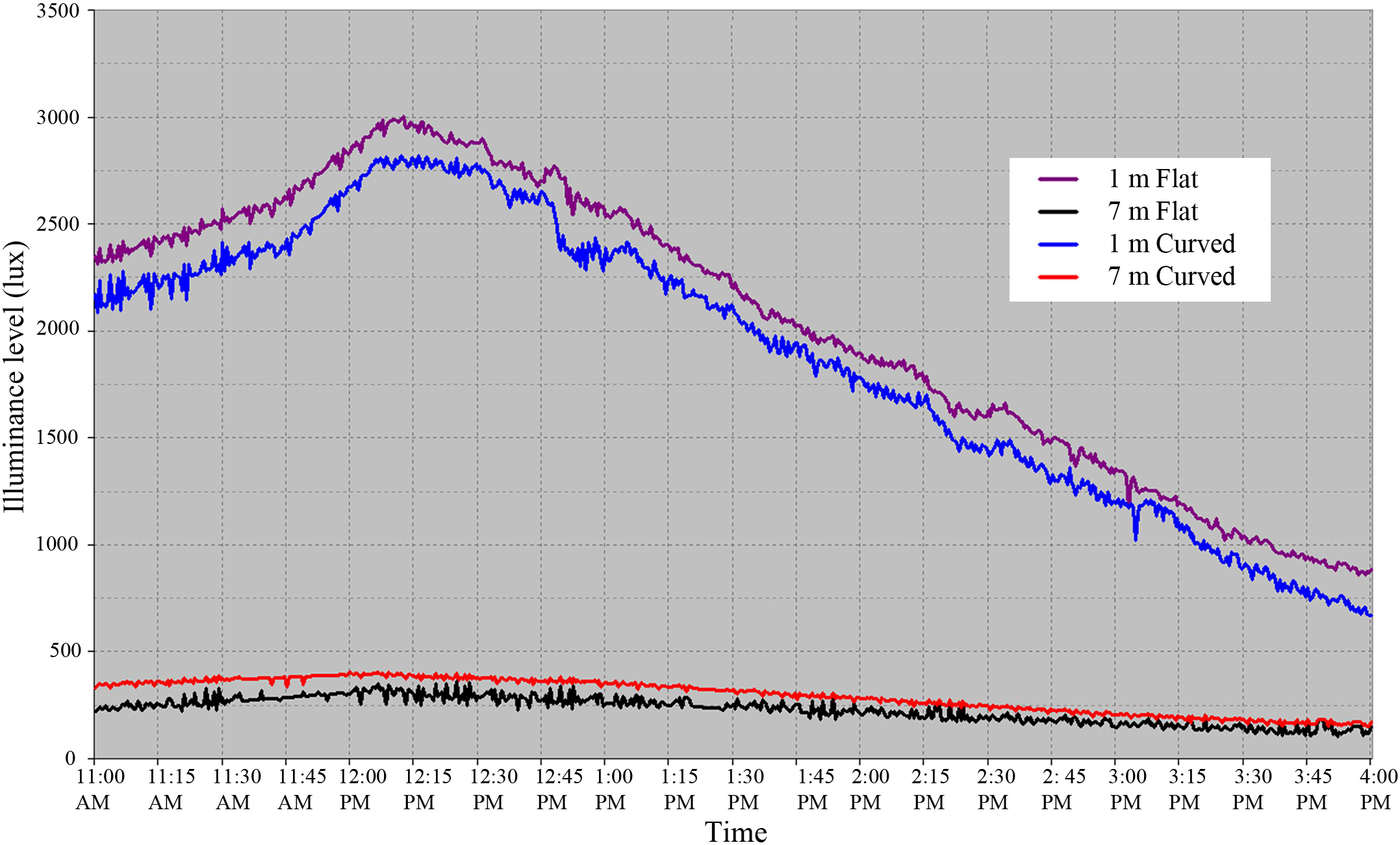

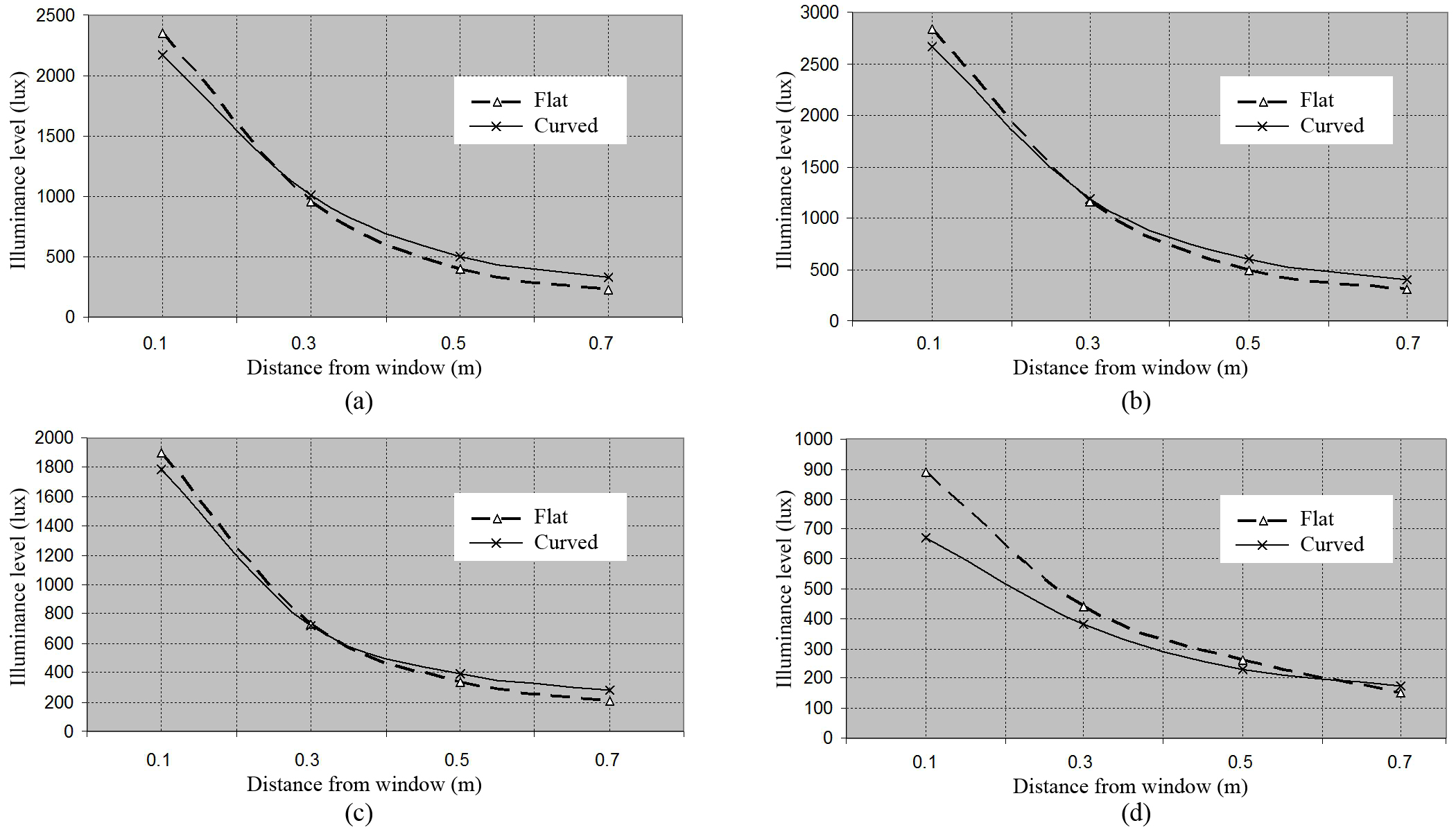

LCP with width to depth ratio (4:6) was used under the real sky condition. The panel was fixed vertically and faced the true south. Flat and curved ceilings for a space of 8 m × 3 m × 3.25 m were examined. The experiments were carried out under clear sky conditions with sun in May for 3 days from 10 am to 4 pm. The results show that LCP tends to reflect more light to the back part of the room, which helps to improve the daylight quality in hot climates. Moreover, the results show that the LCP reflects more light to the rear part of the room with a curved ceiling compared to a flat ceiling. As shown in Figs. 4 and 5, curved ceiling improved the performance of the LCP compared to a flat one. Illuminance level was increased in the back part by an average of 48% and decreased in the front part by an average of 5% on May 4th, while it increased by an average of 50% and decreased by an average of 12% on May 5th. Therefore, the increase in the rear part and the reduction in the front part improve the uniformity ratio from 0.27 to 0.36 for flat and curved ceilings, respectively.

Figure 4

Fig. 4. Illuminance level at 1 m and 7 m from the window for a room served by LCP with curved and flat ceilings on 4th May.

Figure 5

Fig. 5. Illuminance level across the middle line for a room served by LCP with different ceiling geometries at (a) 10 am, (b) 12 pm, (c) 2 pm, and (d) 4 pm on 4th May.

3.2. Radiance simulation

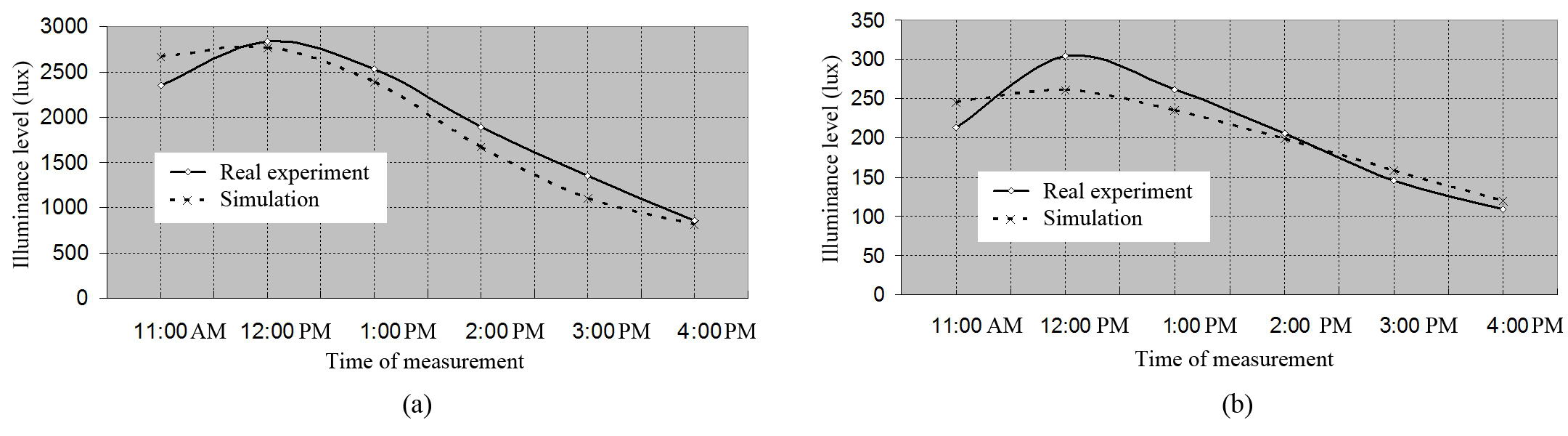

Experiments and simulation results over three days in May showed the ability of Radiance in simulating LCP under clear conditions with sun. The results show a strong correlation between both experimental measurements and simulation results. In Fig. 6, we show simulation and experimental results for LCP in a room, which has a flat ceiling, on 4th May, and Fig. 7 shows a comparison between the experimental and Radiance results for curved ceiling on the same date. The average discrepancies between experiments and simulation are around 16%, 14%, 13%, and 14% at 1 m, 3 m, 5 m, and 7 m from the window for the flat ceiling, respectively. On the other hand, comparisons between simulation and experimental results for curved ceiling showed that Radiance results are matched with the experimental one with averages of 18%, 14%, 13%, and 12% at 1 m, 3 m, 5 m, and 7 m form the window, respectively. The averages discrepancy between radiance and experimental results were 14% and 16% for flat and curved ceilings, respectively. Moreover, the overall discrepancies were 15% 13%, 16% for 4th, 5th, and 6th May, respectively.

Figure 6

Fig. 6. Comparison of experimental and simulation results for a room served by LCP and flat ceiling with ratio (4:5) at (a) 1 m and (b) 7 m from the window.

Figure 7

Fig. 7. Comparison of experimental and simulation results for a room served by LCP and curved ceiling with ratio (4:5) at (a) 1 m and (b) 7 m from the window.

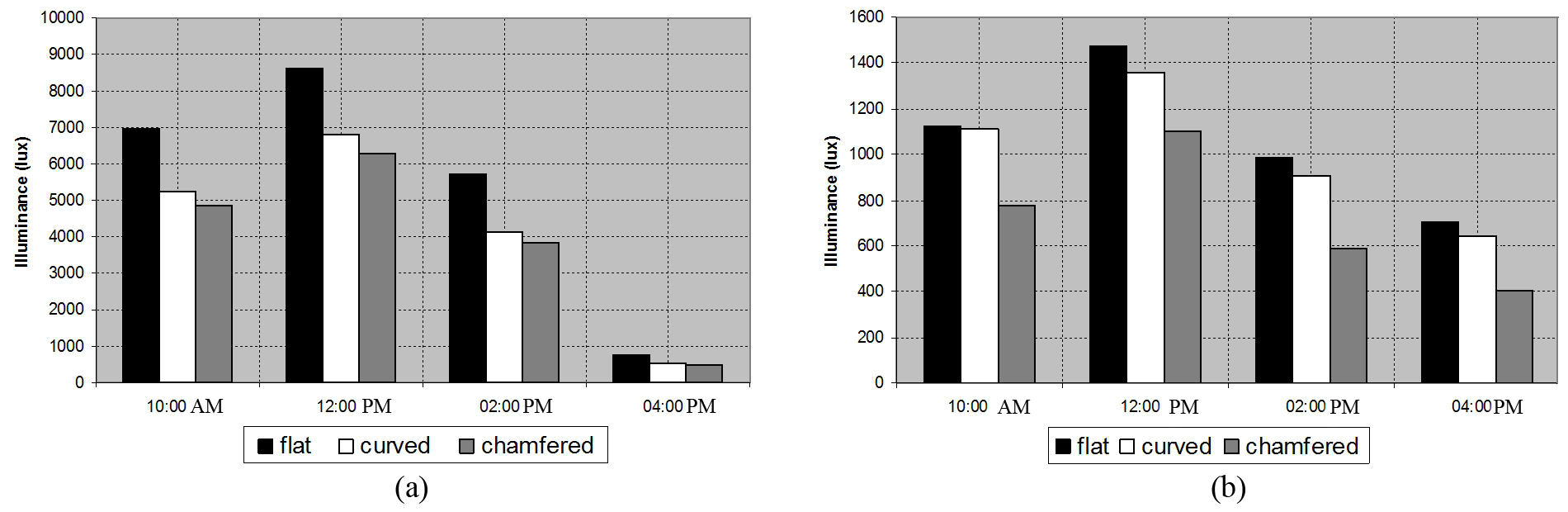

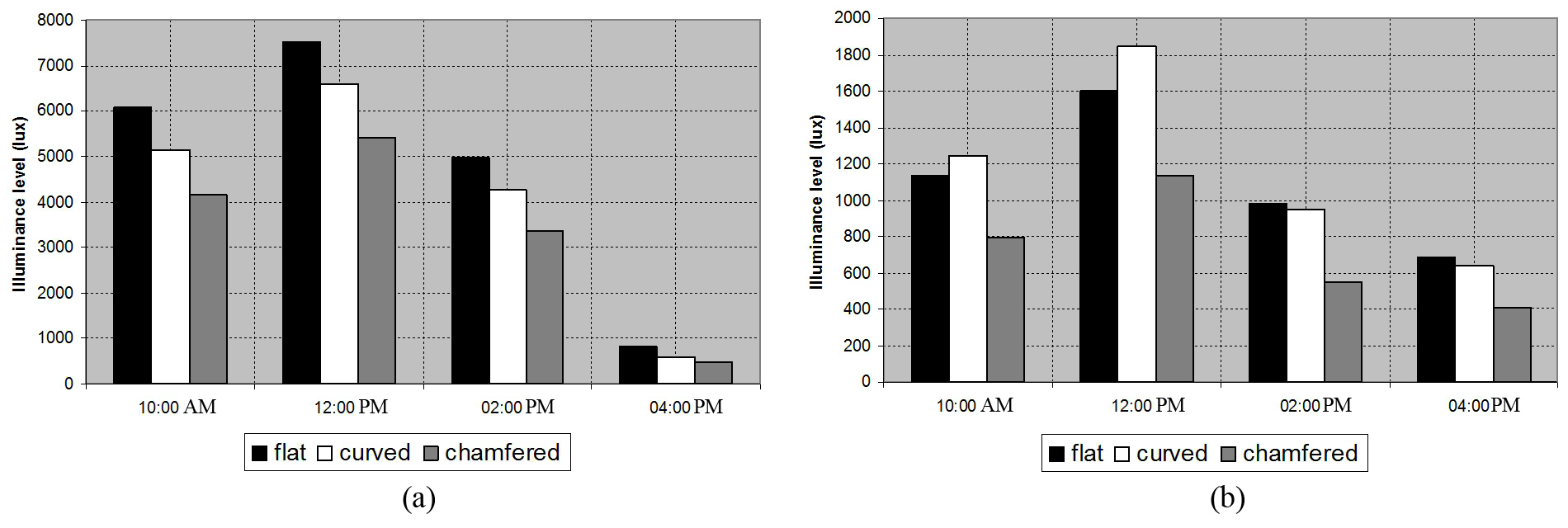

3.2.1 Ceiling geometries

In Figs. 8 and 9, we show how the ceiling geometries improved the LCP performance. It decreased the illuminance level in the front because of using curved or chamfered ceiling that adds well to the LCP performance. Moreover curved and chamfered ceilings helped to increase the illuminance level in the rear part compare to a flat ceiling. Illuminance level increased in the rear part by an average of 40%, 37%, and 35% in March, June, and December, respectively. On the other hand, curved ceiling helped to reduce the illuminance level in the front part by an average of 27%, 6%, and 5% in March, June and, December, respectively.

Figure 8

Fig. 8. Illuminance distribution on the working plane by daylight at (a) 12 PM, (b) 1 PM, (c) 2 PM, (d) 3 PM, (e) 4 PM, (f) 5 PM, and (g) 6 PM.

rved ceiling with ratio (4:5) at (a) 1 m and (b) 7 m from the window.Figure 9

Fig. 9. Illuminance levels in the rear part at 7 m from window in rooms served by LCP with different ceiling geometries (a) 21st March (b) 21st June.

However, chamfered ceiling increased the illuminance level in the back part by an average of 21%, 22%, and 5% in March, June and, December, respectively. Conversely, it decreased illuminance level in the front part by an average of 32%, 35%, and 16% in March, June, and December, respectively. Curved ceiling is more effective in increasing the illuminance level in the rear part, while the chamfered one is more effective in reducing the illuminance level in the front part.

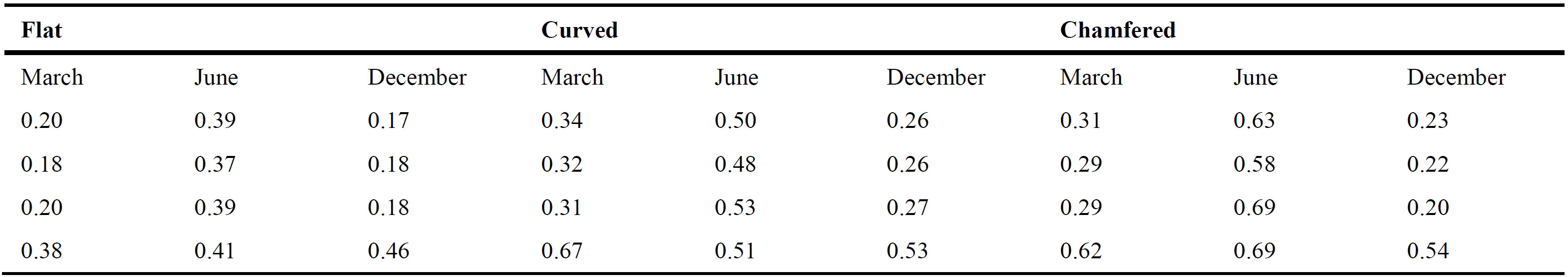

In Table 1, we show that the uniformity ratio, minimum to average ratio, increases as a result of using curved and chamfered ceilings. The uniformity ratio increases from 0.19 for flat ceiling to 0.34 and 0.31 for curved and chamfered ceilings in March, respectively, while increases from 0.38 for flat ceiling to 0.49 and 0.62 for curved and chamfered ceilings in June, respectively. Chamfered ceiling achieved the best results in June, while curved ceiling achieved the best result in March and December.

Table 1

Table 1. Uniformity ratio achieved in the room through LCP (ratio of 4:6) under different ceiling geometries.

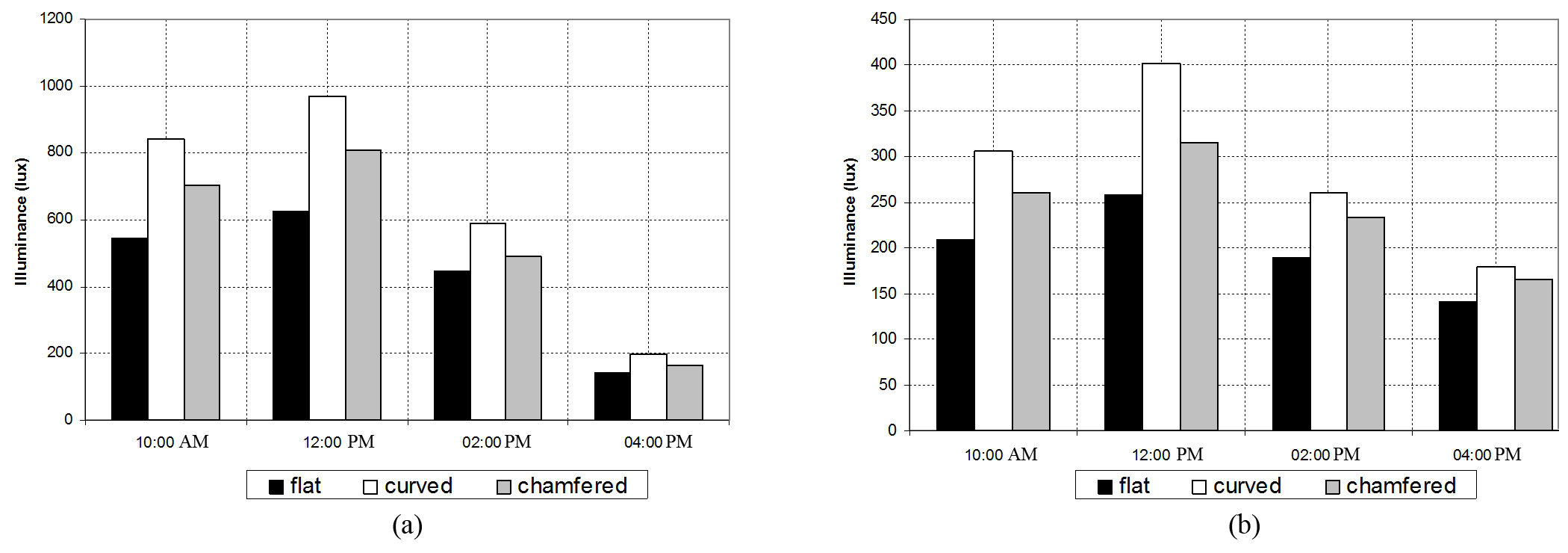

3.2.2 LCP variables

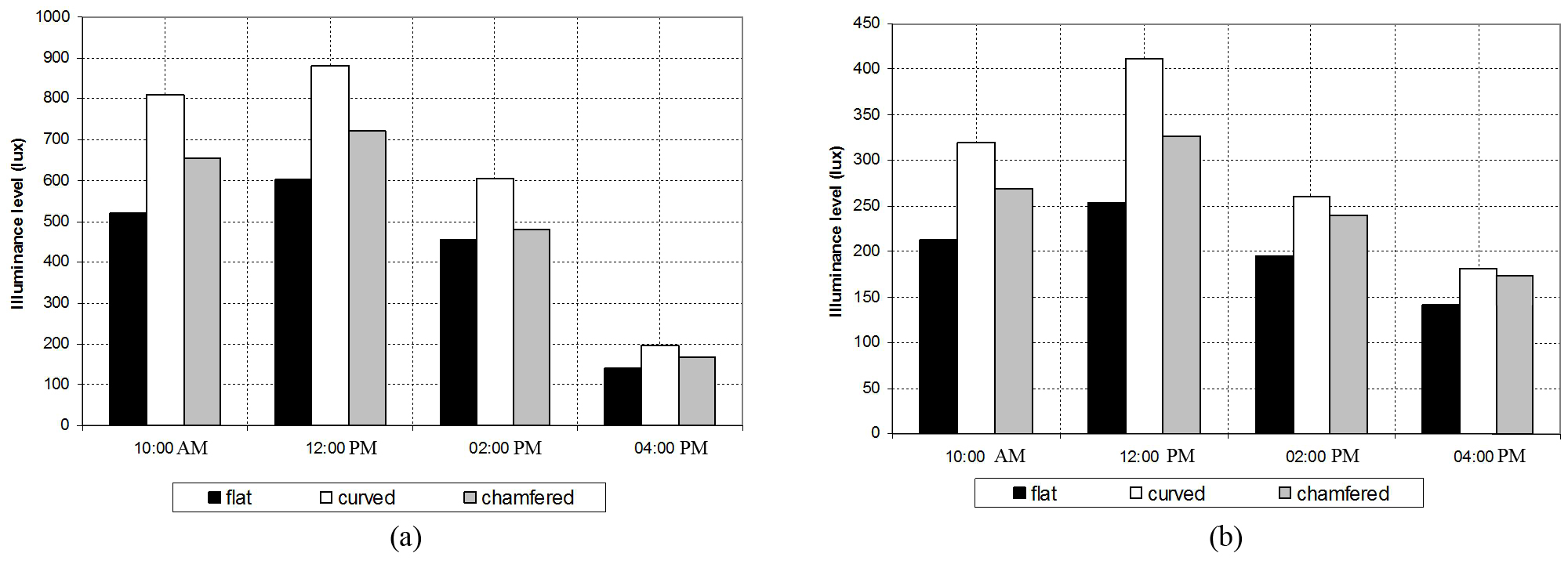

Previous simulations were based on width to cut ratio (4:6) according to the available LCP panel used in the experiments. Meanwhile width to cut ratio (5:6) gives the best performance in terms of percentage of reflected light toward up direction (Fig. 10). Therefore, it will be used with curved and chamfered ceilings to optimize the LCP performance in hot climates. LCP with width to cut ratio (5:6) performs better than LCP with 4:6 ratio with all ceiling geometries (Figs. 10 and 11).

Figure 10

Fig. 10. Performance of the LCP with width to depth ratio (5:6) under different ceiling geometries in front part at 1 m from window on (a) 21st March (b) 21st June.

Figure 11

Fig. 11. Performance of the LCP with width to depth ratio (5:6) under different ceiling geometries in rear part at 7 m from window on (a) 21st March (b) 21st June.

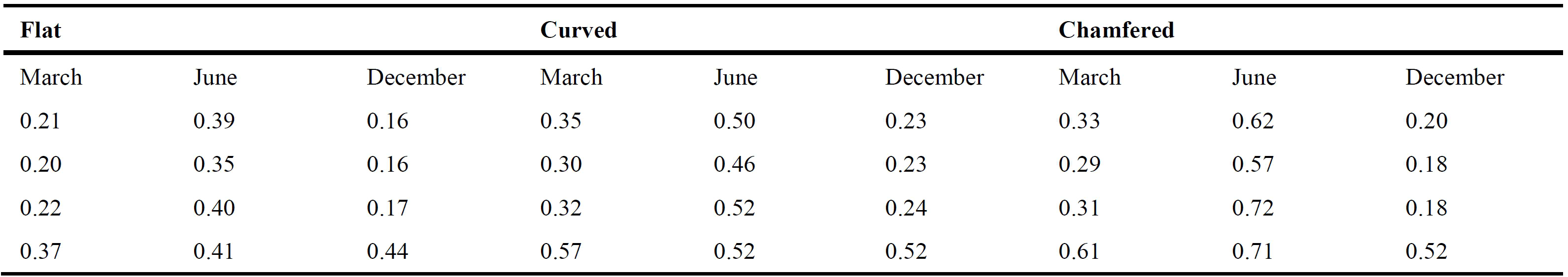

The illuminance level increased in the rear part while decreased in front part. It was increased in the rear part by an average of 15%, 20%, and 18% with flat, curved, and chamfered ceilings, respectively, using LCP with 5:6 ratio compared to 4:6 ratio. Moreover, it was deceased in the front part by an average of 15%, 20%, and 18% with flat, curved, and chamfered ceilings, respectively, using LCP with 5:6 ratio compared to 4:6 ratio. Curved and chamfered ceilings performed better than flat ceiling with LCP. The illuminance level increased in the rear part by an average of 20% and 18% and decreased in the front part by an average of 20% and 18% because of using curved and chamfered ceilings, respectively, compared to LCP with flat ceiling. Furthermore, a comparison was conducted between LCP with 5:6 and 4:6 ratios under curved ceiling in March and Chamfered ceiling in June, as mentioned in Table 2. As a result, uniformity ratio was increased.

Table 2

Table 2. Uniformity ratio in the room served by LCP (ratio of 5:6) under different ceiling geometries.

4. Conclusions

The effect of using different ceiling geometries on the performance of LCP was discussed using computer simulations. Simulations results agreed well with experimental measurements with acceptable discrepancy; therefore, it can be used to optimize the performance of LCP. Moreover, Radiance can confidently be used to study the performance of LCP, following algorithm in [15]. Generally, estimated illuminance in Radiance is less than that of experimental measurement by an average of 8%. Simulation results have shown that there is a positive effect of ceiling geometries on the performance of LCP. Curved and chamfered ceilings have significantly improved the performance of the LCP in the front and rear parts of the room, which is served by LCP. Ceiling geometries combined with LCP increased daylight level up to 22% in the rear part and reduced up to 35% in the front part. The ceiling geometries helped to reflect more light back to the rear part of the studied room, and it helped to reduce the reflected light in the front part at the same time. Changing the LCP aspect ratio from 4:6 to 5:6 improved the LCP performance by an average of 18% with all ceiling geometries.

Curved ceiling greatly improved the performance of LCP by increasing illuminance level in the back part of the room where more light level was favorable. In addition, curved ceiling decreased illuminance level in the front part, which had high light level; thus, it added well to the daylight quality by improving the uniformity of daylight distribution. Curved ceiling improved the daylight performance of LCP more than that of chamfered ceiling.

References

- I. R. Edmonds, Performance of laser cut light deflecting panels in daylighting applications, Solar Energy Materials and Solar Cells 29(1993) 1–26. http://dx.doi.org/10.1016/0927-0248(93)90088-K

- S. Sharples, Lorraine Stewart, and P. R Tregenza, Glazing daylight transmittances: a field survey of windows in urban areas, Building and Environment 36 (2001) 503–509. http://dx.doi.org/10.1016/S0360-1323(00)00018-4

- I.R. Edmonds and D.J. Pearce, Enhancement of crop illuminance in high latitude greenhouses with laser-cut panel glazing, Solar Energy 66 (1999) 255–265. http://dx.doi.org/10.1016/S0038-092X(99)00030-4

- J. Reppel and I.R Edmonds, Angle-selective glazing for radiant heat control in buildings: theory, Solar Energy 62 (1998) 245–253. http://dx.doi.org/10.1016/S0038-092X(98)00006-1

- P.J. Greenup, I.R. Edmonds, and R. Compagnon, Radiance Algorithm to Simulate Laser-Cut Panel Light Redirecting Elements, Lighting Research and Technology 32 (2000) 49–54. http://dx.doi.org/10.1177/096032710003200201

- L. Venturi, M. Wilson, A. Jacobs, and J. Solomon, Light piping performance enhancement using a deflecting sheet, Lighting Research and Technology 38 (2006) 167–179. http://dx.doi.org/ 10.1191/1365782806li167oa

- I. Edmonds, Daylighting high-density residential buildings with light redirecting panels, Lighting Research and Technology 37 (2005) 73–84. http://dx.doi.org/ 10.1191/1365782805li130oa

- I.R Edmonds, P.J Greenup, Daylighting in the tropics, Solar Energy 73 (2002) 111–121. http://dx.doi.org/10.1016/S0038-092X(02)00039-7

- A. A. Freewan, L. Shao, and S. Riffat, Interactions between louvers and ceiling geometry for maximum daylighting performance, Renewable Energy 34 (2009) 223–232. http://dx.doi.org/10.1016/j.renene.2008.03.019

- A.A. Freewan, L. Shao, and S. Riffat, Optimizing performance of the lightshelf by modifying ceiling geometry in highly luminous climates, Solar Energy 82 (2008) 343–353. http://dx.doi.org/10.1016/j.solener.2007.08.003

- M. Tian and Y. Su, An Improvement to Calculation of Lighting Energy Requirement in the European Standard EN 15193:2007, Journal of Daylighting 1 (2014) 16–28.http://dx.doi.org/10.15627/jd.2014.3

- A. Freewan, S. Riffat, and L. Shao, Optimising performance of lightshelf by modifying ceiling geometry, in: World Renewable Energy Council 2006, 2006, Florence, Italy.

- T. Rakha and K. Nassar, Genetic algorithms for ceiling form optimization in response to daylight levels, Renewable Energy 36 (2011) 2348–2356. http://dx.doi.org/10.1016/j.renene.2011.02.006

- A. A. Freewan, Modifying Courtyard Wall Geometries to Optimize the Daylight Performance of the Courtyard, Sustainability in Energy and Buildings 7 (2011) 57–64, Springer Berlin Heidelberg. http://dx.doi.org/10.1007/978-3-642-17387-5_6

- P.J Greenup and I.R Edmonds, Test room measurements and computer simulations of the micro-light guiding shade daylight redirecting device, Solar Energy 76 (2004) 99–109. http://dx.doi.org/10.1016/j.solener.2003.08.018

- J. Mardaljevic, The BRE-IDMP dataset: a new benchmark for the validation of illuminance prediction techniques, Lighting Research and Technology 33 (2001) 117–134. http://dx.doi.org/ 10.1177/136578280103300209

- J. Mardaljevic, Daylight simulation: validation, sky models and daylight coefficients, PhD thesis , De Montfort University, UK, 1999.

- J. Mardaljevic, Validation of a lighting simulation program under real sky conditions, Lighting Research and Technology 27 (1995) 181–188. http://dx.doi.org/ 10.1177/14771535950270040701

- A.A. Freewan, Improving Daylight Performance of Light-well in Multi-story Apartment Buildings, in: SET2011, 2011, Istanbul, Turkey.

- K. A. Al-Sallal and M. M. Bin Dalmouk, Indigenous buildings’ use as museums: Evaluation of day-lit spaces with the Dreesheh double panel window, Sustainable Cities and Society 1 (2011) 116–124. http://dx.doi.org/10.1016/j.scs.2011.05.002

- A. A.Y. Freewan, A. A. Gharaibeh, and M. M. Jamhawi, Improving daylight performance of light wells in residential buildings: Nourishing compact sustainable urban form, Sustainable Cities and Society 13 (2014) 32–40. http://dx.doi.org/10.1016/j.scs.2014.04.001

- A. A.Y. Freewan, Impact of external shading devices on thermal and daylighting performance of offices in hot climate regions, Solar Energy 102 (2014) 14–30. http://dx.doi.org/10.1016/j.solener.2014.01.009

Copyright © 2014 The Author(s). Published by solarlits.com.

HOME

HOME Figure 1

Figure 1 Figure 2

Figure 2 Figure 3

Figure 3 Figure 4

Figure 4 Figure 5

Figure 5 Figure 6

Figure 6 Figure 7

Figure 7 Figure 8

Figure 8 Figure 9

Figure 9 Table 1

Table 1 Figure 10

Figure 10 Figure 11

Figure 11 Table 2

Table 2